Exercise 1. Read the text, try to focus on its essential facts and choose the most suitable heading given below for each paragraph:

1) FMS Is an Automated Production System

2) Early FMSs

3) Modern FMSs

4) Generic FMS Components

FLEXIBLE MANUFACTURING SYSTEM

Flexible Manufacturing System (FMS) is famous for being both a manufacturing technology and a philosophy. "System" is the key word for a flexible manufacturing system. FMS incorporates a system view of manufacturing. The FMS idea was proposed in England (1960s) under the name "System 24". It was a flexible machining system that could operate without human operators 24 hours a day but being controlled by a computer.

The concept of flexible manufacturing systems went on evolving at that time when robots, programmable controllers, and computerized numerical controls succeeded in bringing a controlled environment to the factory floor in the form of numerically-controlled and direct-numerically-controlled machines. Early FMSs were large and very complex, consisting of dozens of Computer Numerical Controlled machines (CNC) and sophisticated material-handling systems. They were too expensive and they were controlled by incredibly complex software.

Currently, the trend in FMS is towards small versions of the traditional FMS, called flexible manufacturing cells (FMC). Today two or more CNC machines are considered a flexible cell and two or more cells — a flexible manufacturing system. The progress of computing machines allowed to introduce a wide scale automation of all branches of industry and led to independent development of automation processes:

— Automated Data Processing: the appearance of Automated Control Systems and Computer Aided Designing (CAD);

— Automation of Production Technology: the appearance of Numerically-Controlled Equipment, Computer-Aided Manufacturing (CAM) and Industrial Robots.

Thus, a flexible manufacturing system is a group of numerically-controlled machine tools, interconnected by a central control system. The various cells for machining are interconnected via loading and unloading stations by an automated transport system. Simply defined, it is an automated production system that produces one or more families of parts in a flexible manner. Today, this prospect of automation and flexibility presents the possibility of producing non-standard parts to create a competitive advantage. Stated formally, the general objectives of FMS are to approach the efficiencies and economies of mass production, and to maintain the flexibility required for small- and medium-lot-size production of a variety of parts. Two kinds of systems for manufacturing fall within the FMS spectrum: assembly systems for assembling components into final products and systems of forming, which actually form components or final products.

General trends of automation

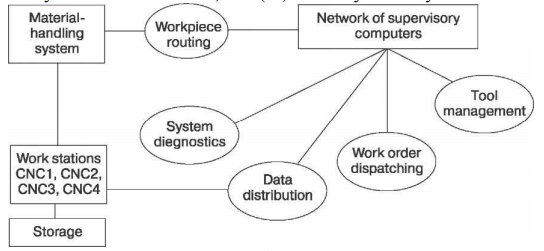

A generic FMS consists of the following components:

— a set of work stations which contain machine tools that do not require significant set-up time or change-over between successive jobs; typically, these machines perform operations of milling, boring, drilling, etc.;

— a material-handling system allowing to move between any pair of machines so that any job routing can be followed;

— a network of supervisory computers and microprocessors which are capable of performing some or all of the following tasks: directing the routing of jobs through the system; tracking the status of all jobs in progress so it is known where each job is to go next; passing instructions for the processing of the operation to the station; ensuring that the right tools are available for the job; and providing the monitoring of correct performance of operations and signaling problems requiring attention;

— a storage, locally at the work stations, and (or) centrally at the system level.

Generic FMS